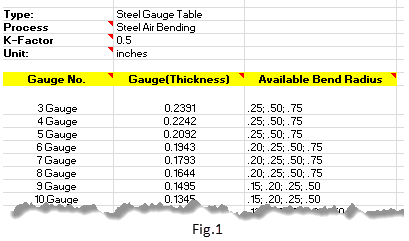

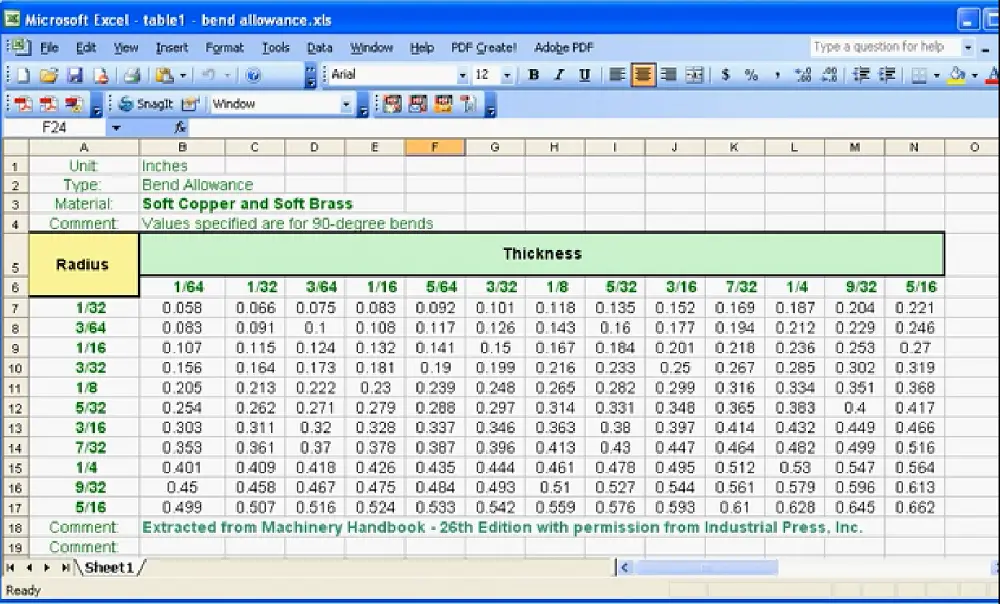

The value of the bend allowance that comes from sheet metal suppliers and manufactures as well as engineering textbooks are provided in bend tables and bend table looks pretty much like the following excel spreadsheet.

Bend allowance table for sheet metal solidworks.

In the featuremanager design tree right click sheet metal and click edit feature.

Using a bend table in a sheet metal part.

Under sheet metal gauges select use gauge table and select a table.

Now to use this table for a sheet metal part all you need to do is to right click on sheet metal feature in the design tree and edit the feature then under bend allowance section select this new custom made table.

To edit the default bend radius bend allowance or bend deduction or default relief type.

Check that you have the sheet metal bend tables folders set not just the templates.

In solidworks this is achieved by selecting the relevant bend allowance options in the sheet metal tool.

How to fix this issue.

Other methods include bend tables k factor and bend calculation.

When working in sheet metal we need to be able take a folded sheet flatten it and have an accurate size flat pattern.

A few items to note about bend tables in a text file.

Bend allowance and bend deduction calculations are methods you can choose to determine the flat length of sheet stock to give the desired dimension of the bent part.

Even though bend allowance table is in my system swx is not detecting it.

If the thickness of the part or bend angle falls between values in the table the software interpolates the values to calculate the bend allowance.

Want all of our free solidworks sheet metal training videos.

Visit our learning library which features all of our training courses and tutorials at http.

The bend table approach is probably the most accurate approach for calculating bend allowance.

The three main options that you will select between are.

The sample bend table is provided only for informational purposes.