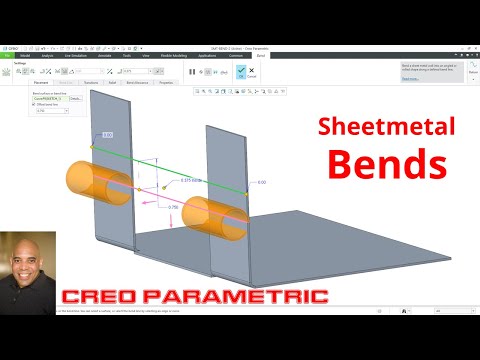

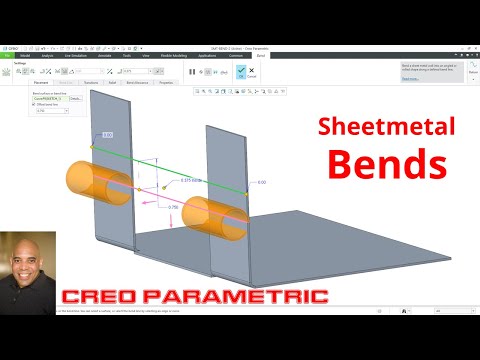

This comprehensive suite of creo sheet metal design tools helps users create features such as walls bends punches notches forms and relief features.

Bend sheet metal creo.

Here end the fabrication formulas for sheet metal up next we ll be seeing some of the terminologies in sheet metal that you ll need.

Bend line shift bls the distance from the outside mold line to the original bend line on the flat pattern this is used to calculate the backstop location when working off of a flat pattern.

What is k factor in sheet metal fabrication.

Start by selecting the bend surface.

When you open legacy models created in creo parametric release 4 0 and previous releases in creo parametric 5 0 the tangent to bend depth option is replace by the on origin depth option.

I thought they added something for this in creo 3 0.

What is the method to create sheet metal bend that has a flat area as shown since bend line in sketch must be one entity.

Ptc was quite proud of it.

Using a variety of y and k factor bend allowance calculations designers can create flat patterns of the designs.

Click edit bend in the mini toolbar.

Creo sheet metal training.

0 kudos reply.

This is a simplified version so i can t use forms or punches.

From creo parametric 5 0 release the depth option tangent to bend in not available.

When the tangent to bend depth option is used in a relation the relation is maintained but the result produced will be the.

You can substitute a bend table for the y factor if you so desire.

Get to know them better to learn advance concept easily.

If i had to i would add the tongue after the bend feature.

Sheet metal modeling and drawing with bend table.

Creo sheet metal tutorial sheet metal bracket 1 in creo parametric duration.

Value of the k factor depends on material bend radius sheet thickness and machines used.

See convert a solid part into a sheet metal part for details.

As sheet metal parts are flattened or formed if you start with a flat state pro sheetmetal utilizes a y factor to allow for the fact that metal is elastic and stretches as it bends.

Mathematically k factor is a ratio of position of neutral axis and sheet thickness.

Just convert the imported 3d model into a creo sheet metal part by defining a driving surface and you re ready to go.

Value of k factor is always less than 0 5.